SCOTCH is ALWAYS GOOOD!!!1Fast68, another consideration here than may have slipped past you is that the sides are NOT a square plank. The longitudinal edges are curved.

If you make a 10" side from one piece of wood with square corners, it's going to have to start out wider than a finished 10".

If you already knew this, then I'll quietly go back to my glass of scotch. (In fact, I think I'll do that no matter what you knew or didn't.)

plywood choices

- Thread starter 1fast68

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TerryKing

Member

Hi Everyone,

I've used many different kinds of plywood. Now I'm building a UncleJohn JonBoat. http://unclejohns.com/jonboat/

12 feet long (Fits in my heated basement shop in the snow in Vermont)...

So Uncle shows 1/4 plywood with at least fiberglass/epoxy joints. Hmm.... I built a 20 foot cuddy cabin with a small block chevy engine, with 1/2 ply and LOTS of fibreglass and epoxy. So that 1/4 inch makes me a little nervous.

But I was was ReadingTheWeb and this forum about plywood and somewhere I heard about "sande" plywood. It's a tropical hardwood from like Guatemala. Goggle and there it is on HomeDepot. LIKE THIS... It's touted elsewhere as often used as marine plywood material, and almost no voids.

So I bought 3 sheets of the 1/4 and one sheet of the 3/4 for $140 I have now cut out the jonboat sides and bottom and done fiberglass butt joints and added 6 oz glass/epoxy on both sides of the sides and the inner bottom. Plan to do bottom outside after assembly with 1 layer of 18oz roaming and 1 layer of 8oz glass.

I cut the seats and seat bulkheads, bow plate and transom out of the 3/4. NICE.. No voids, even in 12 cuts of 4 feet long in the 3/4.

I'll have some build photos up soon. Later, on the Suwannee and Withlacoochee rivers in Florida, I'll let you know how the future goes...

WhatCha Think??

I've used many different kinds of plywood. Now I'm building a UncleJohn JonBoat. http://unclejohns.com/jonboat/

12 feet long (Fits in my heated basement shop in the snow in Vermont)...

So Uncle shows 1/4 plywood with at least fiberglass/epoxy joints. Hmm.... I built a 20 foot cuddy cabin with a small block chevy engine, with 1/2 ply and LOTS of fibreglass and epoxy. So that 1/4 inch makes me a little nervous.

But I was was ReadingTheWeb and this forum about plywood and somewhere I heard about "sande" plywood. It's a tropical hardwood from like Guatemala. Goggle and there it is on HomeDepot. LIKE THIS... It's touted elsewhere as often used as marine plywood material, and almost no voids.

So I bought 3 sheets of the 1/4 and one sheet of the 3/4 for $140 I have now cut out the jonboat sides and bottom and done fiberglass butt joints and added 6 oz glass/epoxy on both sides of the sides and the inner bottom. Plan to do bottom outside after assembly with 1 layer of 18oz roaming and 1 layer of 8oz glass.

I cut the seats and seat bulkheads, bow plate and transom out of the 3/4. NICE.. No voids, even in 12 cuts of 4 feet long in the 3/4.

I'll have some build photos up soon. Later, on the Suwannee and Withlacoochee rivers in Florida, I'll let you know how the future goes...

WhatCha Think??

Sounds like you have it dialed in as far as the boat. The two rivers you also made a great choice on them. Any section of either river has a lot to offer , look out for the Big Shoals on the Suwanee safeties passage is to portage around it.

Hi, Terry. I built 3 kayaks and a canoe. I used okoume 4mil (3/16”) for all. I have one kayak and the canoe. They take a beating on rocks, beaver dams, and a driveway or two in the US and Canada. I think your plywood thickness could be thinner. But, your uses may justify it?

Terry I think you'll be surprised at the strength of the fibreglass over wood for small boats. I often use stich and glue panels of 4 mm cedar strips and 4 oz cloth. I don't baby my boats, and we have 14 grandkids that sure don't! Any way the clear finished get lots of scratches, but we have never broken one.

Good luck with your adventures.

Andy

Good luck with your adventures.

Andy

Nice thing about building your own boat , you can do what you want. Several of my boats ( Numerous Uncle Johns Pirogues , A Uncle Johns Skiff ( 1/4 inch wood ) , a Peterborough Canoe ) except for two Pirogues ( 1/4 inch wood , the other Red Wood strips ) were made from 1/8 Th inch door skin.

I epoxy saturated the wood before glassing it. Then glassed the whole boat so it was encapsulated in fiberglass and epoxy.

The other boats ( a 17 1/2 foot Coho Kayak and 2 , 14 foot Canoes ) were made from a higher quality wood. Again they were epoxy saturated and then glassed like the others. As far as I know all of them are still being used by the folks I gave them to.

The Sasquatch Canoe I still have and it's just as good as when I made it and it has been paddled out west , up north and around here.

The 17 1/2 foot Coho Kayak was the1st ( wood ) boat that I made and it was 22 years ago.

I epoxy saturated the wood before glassing it. Then glassed the whole boat so it was encapsulated in fiberglass and epoxy.

The other boats ( a 17 1/2 foot Coho Kayak and 2 , 14 foot Canoes ) were made from a higher quality wood. Again they were epoxy saturated and then glassed like the others. As far as I know all of them are still being used by the folks I gave them to.

The Sasquatch Canoe I still have and it's just as good as when I made it and it has been paddled out west , up north and around here.

The 17 1/2 foot Coho Kayak was the1st ( wood ) boat that I made and it was 22 years ago.

TerryKing

Member

Bad News, Good News: Amazon buy of West 105b (gallon size) epoxy including 205fast hardener and pumps $160 HERE Package came in with good sized hole in it, and well bent can of 105, with a slight leak. NO packing, just cans in a cardboard box. I complained to Amazon, had good discussion. They said it is non-returnable because it is liquid, BUT since I was a "very good customer since 2004" they would refund the total amount! So used a little 205 on the leak, set it on plastic and kept working. OK so far, used 3/4 at least.

Today I'll be 'building' the UncleJonBoat with side panels already fiberglassed both sides, and bottom fiberglassed on inside. I took a long time over the instructions for cutting the bow plate and transom and their many angles. Later I will post my way to telling about that... Wow... The no-voids 3/4" Sande Plywood looks good...

THANKS for the helpful (and reassuring) comments from all you guys about fiberglassed plywood!

Today I'll be 'building' the UncleJonBoat with side panels already fiberglassed both sides, and bottom fiberglassed on inside. I took a long time over the instructions for cutting the bow plate and transom and their many angles. Later I will post my way to telling about that... Wow... The no-voids 3/4" Sande Plywood looks good...

THANKS for the helpful (and reassuring) comments from all you guys about fiberglassed plywood!

Last edited:

I liked the epoxy from Raka , http://www.raka.com/epoxy.html.

The owner built some of Uncle Johns boats so when I talked with him he knew what was best and could make good recommendations. I would get the medium hardener since I'm in Florida and our heat could increase epoxy curing time.

The owner built some of Uncle Johns boats so when I talked with him he knew what was best and could make good recommendations. I would get the medium hardener since I'm in Florida and our heat could increase epoxy curing time.

Concur on medium hardener. Fast hardener and epoxy is a trap. The cup of mix will boil over, burn you, cause a mess, and waste money.

And, THAT’S the good points of fast gardener!

And, THAT’S the good points of fast gardener!

TerryKing

Member

Hi Everyone,

Just cut the UncleJonBoat seat parts from 3/4" "Sande" plywood.. Not a single void! We'll see how it holds up next few years. I will put out some scrap pieces in the weather with different treatments later... (Cut with my 35 years old Sears "Plytooth" blade.. Similar HERE -- No relation)..

Just cut the UncleJonBoat seat parts from 3/4" "Sande" plywood.. Not a single void! We'll see how it holds up next few years. I will put out some scrap pieces in the weather with different treatments later... (Cut with my 35 years old Sears "Plytooth" blade.. Similar HERE -- No relation)..

Thanks for posting the build With pictures It's good to learn and experience other people's work

TerryKing

Member

Boats are simply magnificent things. Both a tool - and a toy. Paddlers are still little guys, out playing in the sun. Among those that still have hair, some are grayer than others.

But, they all have the same smiles on their faces.

But, they all have the same smiles on their faces.

Is the "sande" plywood from Home Depot made with water resistant glue?

https://www.homedepot.com/p/questio...t-Actual-0-472-in-x-48-in-x-96-in/203414055/5 indicates "not".

When I asked at the store I was told it was for interior use only.

Can there be more than one kind of "sande" plywood?

https://www.homedepot.com/p/questio...t-Actual-0-472-in-x-48-in-x-96-in/203414055/5 indicates "not".

When I asked at the store I was told it was for interior use only.

Can there be more than one kind of "sande" plywood?

TerryKing

Member

Hi, RE: water resistant glue?

HD Does not answer that in any of their online information. What do we have to go on?

- The Sande companies and their corporate companies say Sande is "Often selected for Marine Plywood". No glue comment there, but implied waterproof..

- Several sources I found state that "There is NO plywood made anymore with water-soluble glue, because the large mills all run the same chemistry/glue".

- I also got that answer verbally about 5 years ago from some HD guy on the lumber floor.

So, who are we to BELIEVE?? I'd go with some guys I respect like Dave Carnell, "Dynamite" Payson , Jim Michalak , Phil Bolger and others I forget (sorry!)...

Dave Carnell defined for us All About Epoxy and Acrylic Latex paint (HERE). Jim Michalak has done destructive testing on plywood and glues (HERE). (I captured these on my Wiki because I have been worried they might disappear...)

Jim Michalak BOILED several types of plywood and none delaminated. Read his details on the link above.

So, the Proof Of The Pudding happens on the stove. Tomorrow I will boil samples of the Sande Plywood from Home Depot. Right after I try to sign up for my Vaccination... UPDATE! Got it for the 28th.. Soon I'll be able to do one of my favorite personal indulgences: walk around a really good hardware store for over an hour...

SeeYa!

HD Does not answer that in any of their online information. What do we have to go on?

- The Sande companies and their corporate companies say Sande is "Often selected for Marine Plywood". No glue comment there, but implied waterproof..

- Several sources I found state that "There is NO plywood made anymore with water-soluble glue, because the large mills all run the same chemistry/glue".

- I also got that answer verbally about 5 years ago from some HD guy on the lumber floor.

So, who are we to BELIEVE?? I'd go with some guys I respect like Dave Carnell, "Dynamite" Payson , Jim Michalak , Phil Bolger and others I forget (sorry!)...

Dave Carnell defined for us All About Epoxy and Acrylic Latex paint (HERE). Jim Michalak has done destructive testing on plywood and glues (HERE). (I captured these on my Wiki because I have been worried they might disappear...)

Jim Michalak BOILED several types of plywood and none delaminated. Read his details on the link above.

So, the Proof Of The Pudding happens on the stove. Tomorrow I will boil samples of the Sande Plywood from Home Depot. Right after I try to sign up for my Vaccination... UPDATE! Got it for the 28th.. Soon I'll be able to do one of my favorite personal indulgences: walk around a really good hardware store for over an hour...

SeeYa!

Last edited:

Terry, does this ply have a really thin top laminate? The surface looks very good and that usually means big money or thin laminates.

TerryKing

Member

UPDATE: Not Good Boiling!

Hi, Since it was cheap. probably thin! I'll go measure it...

OK: the 1/4" has veneer of 1.25mm or .05 inch the 3/4 is thinner: .75mm or .03 inch

So, pretty thin but not very different to other hardwood plywood I've used... Here's the 3/4

NEXT: I'll BOIL it... I

UPDATE: I DID Boil It. Not Good News...

After 1/2 boiling it was still intact. After 1 hour boiling the 3/4 delaminated in 2 places and the 1/4 had one veneer loose. Photo:

OK, so.. dealing with Reality (I hate it when that happens, but I'm used to it) : What am I gonna do??

Hi, Since it was cheap. probably thin! I'll go measure it...

OK: the 1/4" has veneer of 1.25mm or .05 inch the 3/4 is thinner: .75mm or .03 inch

So, pretty thin but not very different to other hardwood plywood I've used... Here's the 3/4

UPDATE: I DID Boil It. Not Good News...

After 1/2 boiling it was still intact. After 1 hour boiling the 3/4 delaminated in 2 places and the 1/4 had one veneer loose. Photo:

OK, so.. dealing with Reality (I hate it when that happens, but I'm used to it) : What am I gonna do??

- Epoxy Encapsulate all wood on this build (as planned, but more thoroughly)

- Run the boat and keep Ya'll up to date on how it goes. Yes, I do have PFD,s

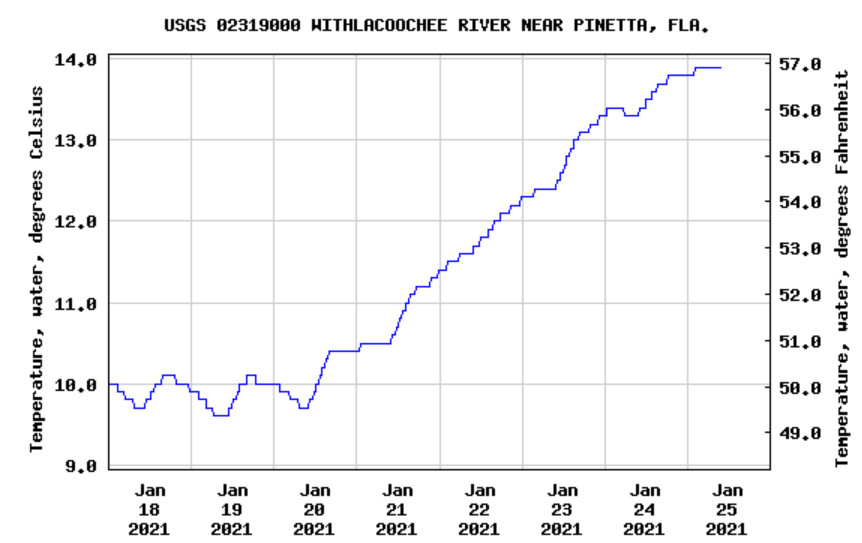

- Check Northern Florida river temperatures. Ahhh. The Withlacoochee rarely boils...

- Do the Naval Inspector thing with the small pointed tool on the wood twice a year.

- Endure the slings and arrows ya'll may feel free to sling....

Last edited:

NEXT: I'll BOIL it...

TerryKing.

I don't meat to step in your post but I know this crew so I'm just reminding them this is the Serious section.

TerryKing

Member

@oldsparkey : OLD?? You call yourself OLD?? (Seriously??) I was born before World War Two STARTED for the USA...

SEE UPDATE ABOVE ON BOILING THE SANDE PLYWOOD :-(

SEE UPDATE ABOVE ON BOILING THE SANDE PLYWOOD :-(

Last edited: